Bags are an essential accessory that has evolved into unique style statements beyond being a useful item. Bag-making is an art that is a fascinating blend of functionality, creativity, and precision. If you’re a bag-maker, these 5 best industrial sewing machines should be included in your facility to help you design beautiful designs. To aid your buying decision, we present the features of top devices from our range of sewing machines from top brands.

Top 5 Industrial Sewing Machines For Bag Making

JACK JK -6591C:

The JACK JK -6591C is a highly efficient and power-saving sewing machine that every bag maker should include in the manufacturing facility. This JACK machine has a roller feed mechanism and a direct drive system, ensuring consistent and smooth material feeding. Post bed sewing design features enable bag shapes by rotating the fabric. This JACK machine series has a simple up-and-down needle function that allows the user to choose in which position the needle stops when the machine stops sewing.

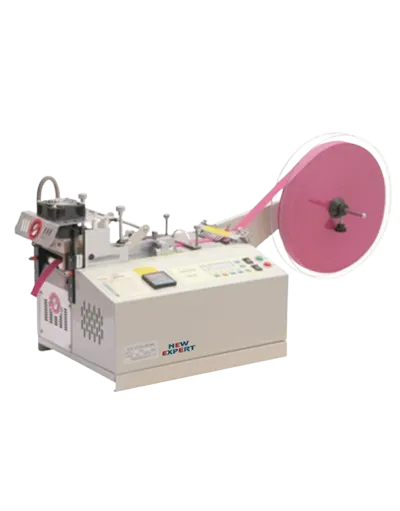

NEW EXPERT KX-110LR:

Bag making process requires precision fabric cutting machines; NEW EXPERT designs the best cutting machines. This high-quality machine is lightweight, portable, and cuts about 50mm long fabric. The stepping motor of the NEW EXPERT KX-110LR enables an accurate cutting length without fraying. The automatic features of the sewing machine stop automatically when the machine runs out of fabric. This NEW EXPERT machine does not apply to pure cotton fabric.

NEW EXPERT KX-243:

This machine is designed to handle tough materials effortlessly. The machine has a powerful feed system that allows accurate stitching of heavy materials generally used in making bags. This NEW EXPERT KX-243 sewing machine has a pressure foot lift for up to 20mm, enabling the stitching machine to stitch multiple layers of fabric effortlessly. This heavy-duty machine is suitable for sewing different fabrics like denim, canvas, and leather.

JUKI LU 2810:

The JUKI LU 2810 Sewing machine is designed to sew medium to heavy-weight materials such as leather, canvas, and vinyl, which are often used in bag manufacturing. The machine’s walking foot and unison-feed characteristics enable uniform feeding of the material, which is essential when stitching thick layers of fabrics usually required to make bags.

NEW EXPERT KX-205:

Complete your lineup with the NEW EXPERT KX-205, which has a bobbin winder and a semi-rotary large shuttle. The rotary shuttle increases work efficiency and reduces the frequency of bobbin changing. The machine features a cylinder bed with a thin, cylindrical shape that allows it to stitch in tight spaces like on bags. The KX-205 is a compound feed machine, which ensures that the fabric is moved through the machine by a feed dog, needle, and presser foot.

Things to Consider Before Buying An Industrial Bag Sewing Machine

Now that you know the best machines you need in your facility to design bags, let’s shed some light on what you should consider before buying one.

Type of bags:

Determine the specific types of bags you intend to manufacture. Different types of bag materials and designs require sewing machines with specific features. If you are in leather bag production, you will need a heavy-duty sewing machine that handles tough materials like leather.

Production volume:

Assess the production scale to see if you are creating bags on a small or large scale. This will influence the decision to buy a machine with a high-speed motor with advanced features. Different production volumes require machines with varying features like needles, workspace, and portability.

Types of stitches:

Before you purchase a sewing machine, assess the types of stitches the machine can produce. Different bag designs require different stitch patterns and have versatility in stitching aspects to enhance creative possibilities.

Ease of use:

Consider the user-friendliness of the bag sewing machines to make your artisan’s life easier. Include machines with features like easy threading, controls, and automatic features that can also contribute to smooth learning of the machine operations.

Maximise Bag Production with Best Sewing Machine for Bag Making

Increase the production of bags with the best industrial sewing machine for bag making that suits your purposes. Above, we added the top 5 sewing machines for bag making made specifically to cater to the requirements of a bag maker. Whether you are stitching thick material, such as leather, or small, complex designs on sheer materials, these sewing machines provide the muscle, speed, and flexibility needed to increase your productivity.

Starting from the robust Jack JK-6591C to the new Expert KX-205, every product is rightly chosen to improve your daily workflow. Buy the best sewing machine for bag making today and see your skills soar to the next level.

Conclusion:

The right machines play an essential role in making or breaking the bag manufacturing process. It is evident that sewing machines are essential in crafting durable and beautiful bags, and these six machines make it easier for you. Every machine from our bag stitching range has the best features that cater to the diverse needs of the bag types.

As a supplier of sewing machines, Balaji sewing machine has durable machines that deliver accurate and precise stitches to help design unique products. Browse our website to learn about the different sewing machines and their unique features. Choose from our range of machines that will help you design beautiful bags and effortlessly improve your production process.