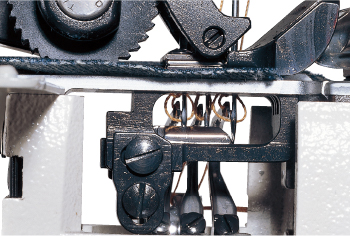

The looper tucks the thread without fail, thereby preventing stitch skipping

The placement of the feed mechanism has been charged to decrease the feed amount when the needle enters the material, thus preventing the needle from bending. The bobbin thread is clamped without fail, thereby producing consistent thread loops. The looper tucks the needle thread without fail, thereby finishing uniform seams.

-

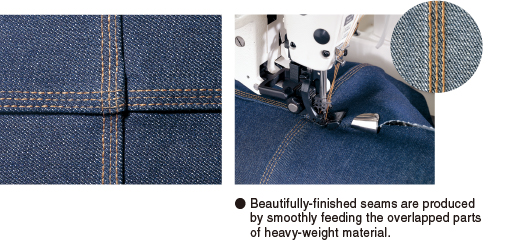

The feed mechanism smoothly feeds the material, thereby allowing the machine to finish seams with consistency

The number of teeth of the feed dog has been increased so that it can easily catch overlapping material. The shape of the presser foot has been modified to prevent single-sided contact with the overlapped part. The movable needle guard (rear) is provided with a vertical adjusting mechanism. These features contribute to smoother feed of heavy-weight materials, thereby preventing stitch skipping.

-

The machine provides beautifully-finished seams even when heavy-weight material is used

Thanks to the thread guide located between the needle bar thread take-up and the intermediate tension release lever, the timing to tense the needle thread can be changed and the bobbin thread tension can be decreased. As a result, the machine is capable of beautiful finished stitches with a soft appearance even when heavy-weight material is used.

-

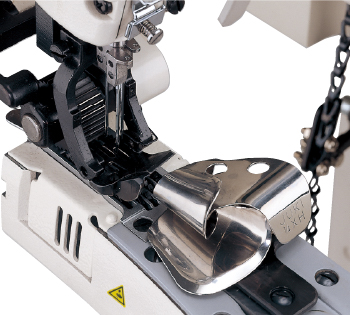

The machine prevents uneven material feed

Differences in height between the feed dog and the sole of the presser foot can be appropriately specified and adjusted in accordance with the material thickness. Folders allow the material to be smoothly fed and the cloth puller (optional) has improved fulcrum so that it can run on the material and prevent uneven material feed.

JUKI MS-1261 Feed-Off-The-Arm, Double Chainstitch Machin

Product Overview:

If your workshop handles denim, uniforms, or heavy-duty trousers every day, the JUKI MS-1261 makes life easier. This industrial-grade, feed-off-the-arm double chainstitch machine is tailor-made for tubular garments, sleeves, side seams, and inseams all done without stress or mess. It’s not just about stitching fast; it’s about doing it right, again and again.

Key Features:

Why do garment factories across India rely on this model?

- A Workhorse for Side Seams: Whether it’s jeans, cargo pants, or workwear, this machine powers through thick fabrics with ease.

- Keeps Pace Without Losing Quality: It stays stable and precise, even when you’re running it full speed on long shifts.

- Smart Arm Design: The feed-off-the-arm setup makes it simpler to manage tubular pieces — no bunching, no awkward handling.

Real-World Benefits:

Not just a piece of machinery this is a serious production boost.

- Get More Done, Faster: The MS-1261 is made to reduce time at every seam, helping you hit targets without burnout.

- Less Strain, More Flow: Operators can move quickly without constantly adjusting fabric — less effort, better results.

- Strong, Clean Seams: It delivers consistent stitching that holds up on the job, even with heavy materials like denim or canvas.

Why Balaji Sewing?

Because the right partner makes all the difference.

- Trusted JUKI Dealer in India: You’re getting the real deal with factory warranties and after-sales peace of mind.

- Support That Travels: From Delhi to Coimbatore, we deliver fast and follow through with professional servicing.

We Train Your Team: Our technicians don’t just install the machine they show your crew how to use it confidently from day one.

Reviews

There are no reviews yet.