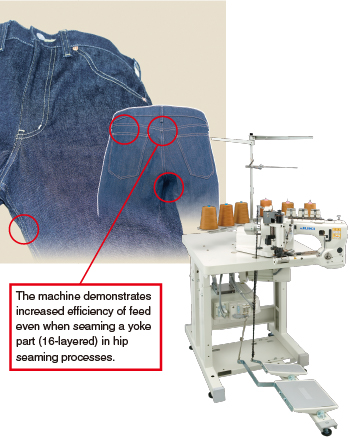

The machine is best suited for lap seaming jeans, denim jackets, work uniforms, etc. constructed of heavy weight materials

The machine demonstrates increased efficiency of feed even when seaming a yoke part (16-layered) in hip seaming processes.

-

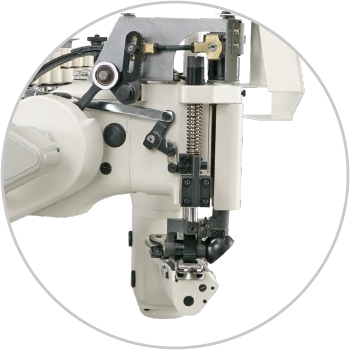

Strong feeding mechanism of the puller

The puller incorporates a one-way clutch mechanism which contributes to consistent feeding of the material.

(The mechanical part is protected by a cover for added safety.)

-

Thread take-up device which helps produce even stitches with consistency

The feeding amount of needle thread is automatically adjusted to the pressure foot height during sewing, thereby producing even stitches with consistency.

-

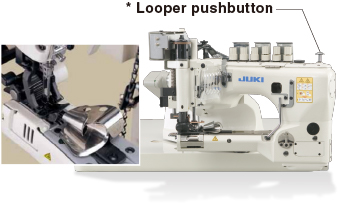

The machine has been designed to achieve the best possible ease of threading

When the looper pushbutton (*) located on the operator side of the top of the machine head is pushed, the tip of the looper moves downward to allow the operator to thread the machine head with ease.

-

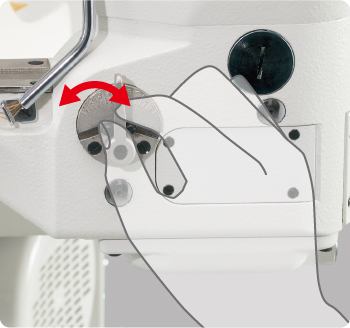

The differential feed adjusting lever is located on the front face of the machine head

The differential feed adjusting lever can be adjusted even during sewing, thereby effectively preventing cloth slippage between two plies.

Reviews

There are no reviews yet.